IBE production technology is an innovative method of manufacturing mineral wool products from basalt raw material. Compared to conventional production methods, the IBE process has a significantly higher efficiency. Mineral wool fibers produced in this process have a higher elasticity and are more resilient. The insulation boards thus manufactured are lighter and more stable than conventional rock wool boards.

We offer our customers economical constructive solutions based on our innovative melting technology of mineral raw materials as well as innovations in other production steps.

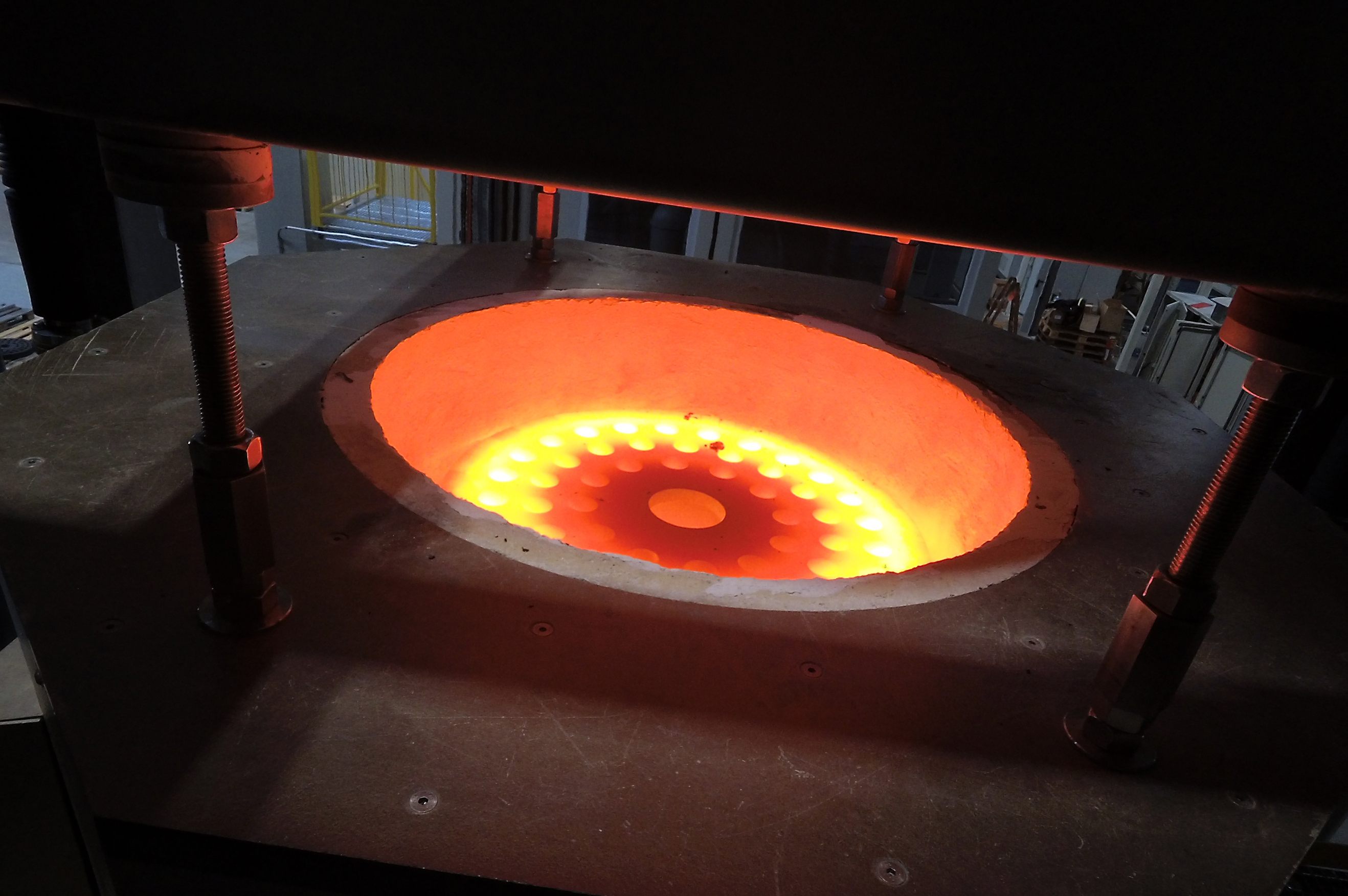

Hot End (Melting Unit)

The melting of raw material components takes place in the IBE melting device, the latter being an advanced design of inductively heated crucible furnace. Conventional technology: cupola furnace (coke/gas), gas furnace or electrode furnace of …

More

Fiberizing & Felt Formation

Fiberizing & Felt Formation The fiberizing and felt formation system developed by IBE allows to adjust the density and thickness of felt as well as binder percentage in every single felt collection chamber. Thanks to …

More

Drying/Curing

Drying/Curing Chamber Unlike conventional hardening furnaces, the IBE drying and curing system operates on the principle of dielectric drying. The main advantage of this method is a homogenous warming-up of the mineral wool fleece made …

More

Length Saw

Length Saw The innovative IBE length saw provides a plenitude of choices for cutting mineral wool plates. 6 autonomous saw heads for maximum flexibility at choosing the board width fully automated positioning of saws edge …

More