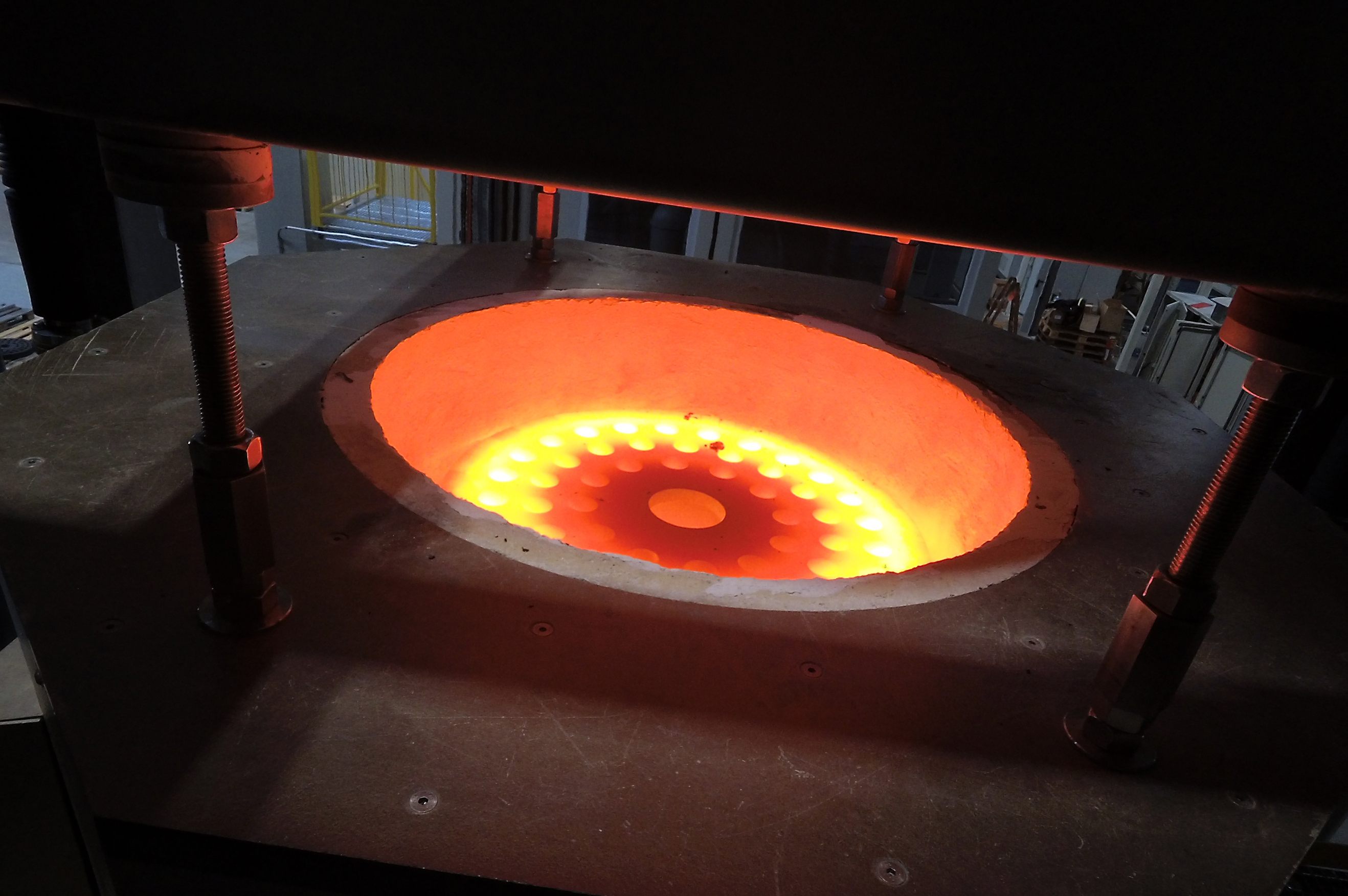

The melting of raw material components takes place in the IBE melting device, the latter being an advanced design of inductively heated crucible furnace.

Conventional technology:

- cupola furnace (coke/gas), gas furnace or electrode furnace

of high volume

Disadvantages:

- changing composition of melt takes a long time

- energy consumption

- exhaust gases

Inductive melting:

- minor melting volume

- adjustable temperature control

- higher efficency

- flexibility (fast activation and shutdown)

- possibility of thermal treatment

- no burn-off of electrodes