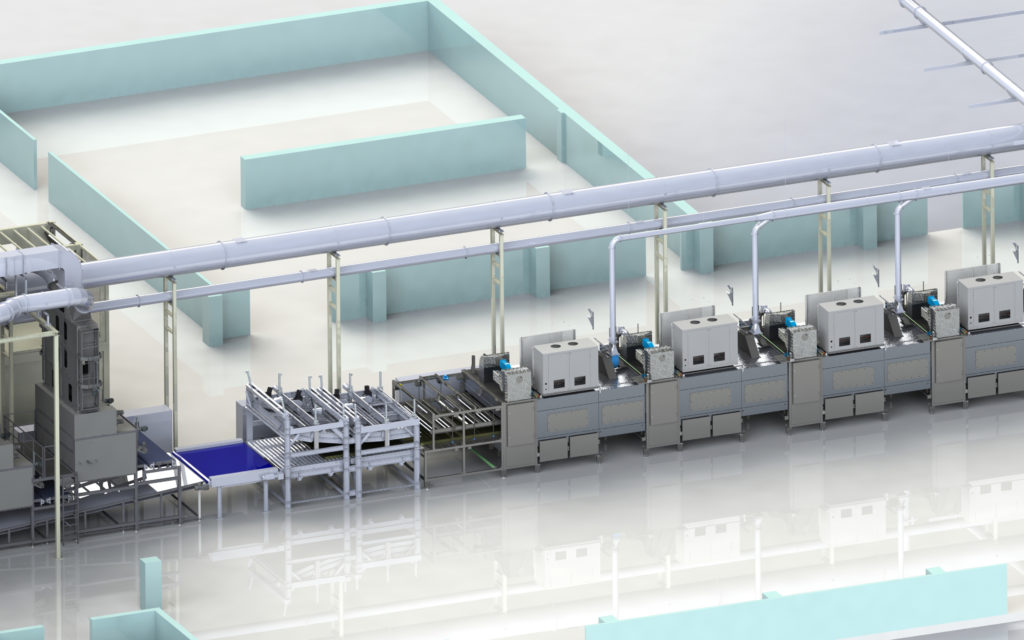

Drying/Curing Chamber

Unlike conventional hardening furnaces, the IBE drying and curing system operates on the principle of dielectric drying. The main advantage of this method is a homogenous warming-up of the mineral wool fleece made possible by a high-frequency alternating electric field applied at material with according properties.

Conventional drying/curing is done with hot air:

- The air flows through the panel.

- In case of high thickness of panels and high densities this principle gets to its limits (heating of an insulator).

- Outer zone is hardened first, the core determines the process time.

Alternative technology: dielectric drying

- energy input via condenser plates

- homogenous warming up of the product across the entire cross-section

- utilization of reaction energy (exothermal process energy)

Advantages:

- lower energy consumption

- less space required

- modular construction

- no cooling zone needed