News

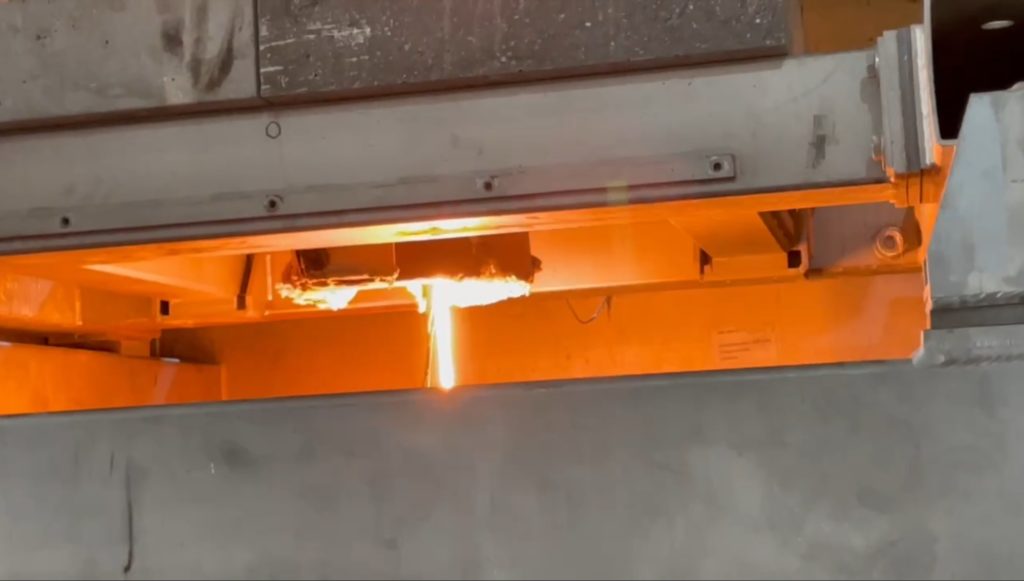

COMMISSIONING OF INDUCTION MELTING UNIT AT JIZZAX PLANT

On 10/01/22, the 25,000 ton induction melting unit for melting of basalt was launched at the Jizzax plant (Uzbekistan). Installation and commissioning on the rest of the production line continue.

Comparative Analysis of Basalt, Andesite, and Andesibasalts as Raw Materials for Continuous Fiber Production and Promising Deposits

The production of continuous fibers based on basalt, andesite, and andesite basalts is gaining increasing popularity due to the high strength, thermal stability, and chemical resistance of these materials. This article examines the technical and technological aspects of using these minerals for fiber production, their operational properties, the chemical durability of the products, and the most promising deposits that can serve as raw material sources for the industry.

- Comparative Composition and Properties of Minerals

To compare basalt, andesite, and andesibasalts, it is important to consider their typical chemical composition, which determines key fiber properties such as strength, thermal stability, and resistance to acids and alkalis.

Chemical Composition of Basalt

Basalt is the primary type of igneous rock, and its chemical composition varies within the following ranges:

- SiO₂ (Silicon Dioxide): 45–52%

- Al₂O₃ (Aluminum Oxide): 12–16%

- Fe₂O₃/FeO (Iron Oxides): 9–14%

- MgO (Magnesium Oxide): 5–12%

- CaO (Calcium Oxide): 6–12%

- Na₂O + K₂O (Alkali Oxides): 2–5%

- TiO₂ (Titanium Dioxide): 1–3%

Basalt has a high content of iron and magnesium oxides, which gives the material high strength, thermal resistance, and alkali resistance.

Chemical Composition of Andesite

Andesite, being a more acidic type of volcanic rock, has the following typical composition:

- SiO₂ (Silicon Dioxide): 55–60%

- Al₂O₃ (Aluminum Oxide): 17–20%

- Fe₂O₃/FeO (Iron Oxides): 4–6%

- MgO (Magnesium Oxide): 2–4%

- CaO (Calcium Oxide): 6–7%

- Na₂O + K₂O (Alkali Oxides): 3–7%

- TiO₂ (Titanium Dioxide): 0.5–1%

Andesite has a higher content of silica and aluminum compared to basalt, providing it with high acid resistance but reducing its resistance to alkalis.

Chemical Composition of Andesibasalt

Andesibasalt is a transitional rock between basalt and andesite, and its chemical composition can vary:

- SiO₂ (Silicon Dioxide): 50–55%

- Al₂O₃ (Aluminum Oxide): 15–18%

- Fe₂O₃/FeO (Iron Oxides): 6–10%

- MgO (Magnesium Oxide): 4–8%

- CaO (Calcium Oxide): 6–10%

- Na₂O + K₂O (Alkali Oxides): 2–5%

- TiO₂ (Titanium Dioxide): 1–2%

The silica content in andesite basalts is higher than in basalt but lower than in andesite, making these rocks moderately resistant to both acids and alkalis. Andesite basalts combine the strength and thermal resistance of basalt with the chemical resistance of andesite, making them attractive for fiber production.

- Technological Aspects of Fiber Production

Basalt

The production of basalt fibers has long been established and occurs by melting the rock at temperatures of 1300–1400 °C, followed by fiber formation. This process is relatively simple and cost-effective.

Andesite

Andesite melts at a slightly higher temperature—around 1500 °C—requiring more precise equipment adjustments. Andesite fibers are promising due to their high acid resistance, but their industrial application is still in the development stage.

Andesibasalts

Fiber production from andesibasalts is also possible at melting temperatures around 1400–1500 °C. This direction represents a promising area for research, as such fibers may combine the advantages of both minerals.

- Chemical Resistance of Products

Basalt Fibers

Basalt fibers are resistant to alkalis due to their low silica content, making them suitable for use in alkaline environments. However, they are less resistant to acids.

- Acid Resistance: Moderate, destroyed by strong acids.

- Alkali Resistance: High.

Andesite Fibers

Due to their high silica content, andesite fibers exhibit high acid resistance but are less resistant to alkali exposure.

- Acid Resistance: High.

- Alkali Resistance: Low.

Andesibasalt Fibers

Andesibasalts combine the properties of basalt and andesite, providing them with high acid resistance and moderate alkali resistance.

- Acid Resistance: Higher than basalt.

- Alkali Resistance: Lower than basalt but better than andesite.

- Operational Properties of Products

Basalt Fibers

- Thermal Resistance: Up to 1000 °C.

- Application: Insulating materials, reinforcing composites, fire-resistant products.

Andesite Fibers

- Thermal Resistance: Up to 800–900 °C.

- Application: Promising for use in high-acid environments and thermal insulation.

Andesibasalt Fibers

- Thermal Resistance: Up to 1000 °C.

- Application: Combined environments with exposure to acids and alkalis, structural materials, composites.

- Promising Deposits of Andesibasalts

- Far East and Siberia, Russia

In the Far East and Eastern Siberia, including Kamchatka and the Kuril Islands, andesite basalt flows are widespread, making these regions promising for raw material extraction for fiber production. - Carpathians, Ukraine

The Transcarpathian region is known for its deposits of andesites and andesite basalts. Resource development for fiber production based on andesite basalts is possible in this area. - Andes Mountain Range, South America

Deposits of andesite basalts in Chile and Peru have enormous potential for industrial extraction due to rich volcanic zones and developing infrastructure. - Central Europe

Volcanic belts in Germany (Rhenish Massif) and the Czech Republic also contain andesite basalt rocks, making this region an important source of raw materials. - North America

The Cascade Mountains in the USA and Western Canada are rich in volcanic rocks, including andesite basalts, opening up prospects for fiber production.

Conclusion

To produce continuous fibers, basalt remains the primary material due to its availability and good operational properties. Andesite and andesibasalts present promising alternatives, especially in conditions requiring high acid resistance. Andesibasalts could serve as raw materials for fibers that combine the strength of basalt with the chemical resistance of andesite. The andesibasalt deposits in Russia, Ukraine, South and North America, as well as Central Europe, have tremendous potential for development, which could play a key role in the advancement of this industry.

Dr. Victor Bartashov

What are the advantages of recycling fibrous waste using IBE technology?

- Eliminates the costs of briquetting and disposal of your own production waste

- Allows you to produce additional commercial products not only by using your own waste (up to 15% of the output volume), but also by attracting up to 30% or more construction fibrous waste with a negative price -300÷350 euros per ton, thereby also significantly reduces production costs

- Due to the use of induction heating in the melting furnace instead of coke and dielectric heating in the polymerization furnace instead of gas, the specific energy consumption can be reduced by almost 2 times

- Eliminates carbon dioxide emissions (almost 0 instead of 800÷900 kg/t of finished products)

- Reduces unit costs for personnel due to a significantly higher degree of automation, mechanization and control of the technological process, which also reduces production costs and the cost of finished products

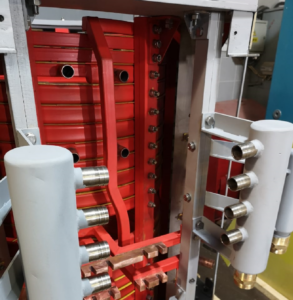

Electric melting and composite die (bushing) to produce basalt continuous fiber.

Our company has developed platinum-free dies for Continuous Basalt Faber (CBF) with several quantity of holes from 200 to 600 and conducted their comprehensive tests.

Equipment designed to implement our technology consists of:

- Loading device for primary basalt fraction from 0 to 8 mm without any pre-processing (washing, sorting, etc.)

- Induction melting furnace with a specified temperature profile in four zones

- InLine mixer (a new one!)

- Electric feeder for 10 outlets

- 10 composite spinneret feeders (bushings)

As a result, a highly stable process to produce CBF has been developed, which includes high-speed induction melting of basalt, high-temperature heat treatment and low-temperature “casting” of filaments. The process makes it possible to improve the quality of basalt threads across the entire range of their diameters, line productivity by an average of 15%, and eliminate thread breakage during drawing.

Economic and operational characteristics of the above equipment set:

- Energy consumption per 1 ton of fiber 820 kWh

- Die output at 608 holes >30 kg/h

- The test period for the composite die was 90 days of continuous operation, the die (bushing) remained fully functional

- The diameter of the resulting fibers 9-16 µ, – depends on the drawing speed

- Price ratio compared to PtRh die (bushing) 1/15

During the tests there was not a single breakage of the drawn threads.

Works to increase performance of equipment will are continues.

Technical data of the Melter IBE70-3.2

• Capacity to continuously melt in 24/7 x 2 mode for basalt with an acid

modulus in the range of 0.9-2 7,23 t/h

• Complete crucible:

HTiegel= 2.732 mm

DTiegel= 1.156 mm

Weigt= 3.037 kg

• Double inductor:

Diameter: 1.176 mm

Height: 2.340 mm

• Specific power consumption 653 kWh/t

• Generator output (installed) 5.700 kW

• Energy losses 91 kWh/t

• Efficiency of the melting unit 86%

Working temperature:

Melting zone: 1.270°C

Heat treatment zone: 1.600°C

Casting zone: 1.470°C (adjustable)

IBE70-3.2

New induction unit IBE70-3.2 for melting mineral substances (dispersed glass, stone, various oxides and their mixtures, including fibrous waste and dust) of continuous operation in the temperature range from 1.100 to 2.100 ° C with a capacity of up to 7 t / h. Details on request.

MERRY CHRISTMAS AND A HAPPY NEW YEAR

We wish our customers, business partners and colleagues a Merry Christmas ️and all the best for 2023!

Recy & DepoTech Conference

Our company attended the 16th Recy & DepoTech Conference. It took place in Leoben, Austria from November 9th to 11th. Our lecture “The inductive inline furnace for recycling and utilization of mineral waste and residues” was received with interest. The paper is available for download.. Vortrag_IBE_DepoTech2022

METHOD FOR WASTE-FREE MANUFACTURING OF MINERAL WOOL INSULATION PRODUCTS

On October 15, 2022, our patent “Method for waste-free production of thermal insulation products from mineral wool” (AT 524875, priority dd. August 16, 2021) was published.

The invention relates to a cost-effective, environmentally friendly and resource-saving method for the manufacturing of insulation products from mineral wool, in which at the production section (A) the melt produced in a cupola or in an electric arc or gas melting furnace is fed to fiber formation unit and processed step by step into a mineral wool product.

The invention is based on the unique advantage of the in-line induction melting furnace developed by IBE, which allows to produce a continuous flow of melt from a mixture of granular and fibrous raw material with a grain size of up to 12 mm in any proportion.

By adding a production section (B), in which granular (mainly shots and fine-grained fraction of the feedstock) and fibrous production waste from both production sites are melted in the in-line induction melting furnace and processed into mineral wool products, the problem of waste-free production is solved.

The need for briquetting or waste disposal is thus eliminated. Besides, there is no need to add crushed production waste, which reduces the quality of the final product, to the newly produced fibers.

Mineral raw materials (basalt and dolomite) can be additionally fed into the in-line induction melting furnace, which allows to increase the total production volume at a relatively low cost.

Advantageously, both production sites have coordinated production planning and control, as well as a common infrastructure, including power supply and utilities, automation, logistics, raw material processing, production waste processing, binder processing, packaging, maintenance and repair.

Patent AT524875: https://www.ibe.at/publications/

IBE loose stone wool

IBE loose stone wool is an efficient and economical thermal insulation material consisting of impregnated mineral wool fibres. This product can be manufactured even after the completion and putting into operation of the melting and fiberizing unit as part of the complete production line. It can be easily pulled apart and is therefore particularly suitable for filling in cavities that are difficult to access or complex construction parts. Like as stone wool in general, IBE loose stone wool is non-flammable (building material class A1), heat and sound insulating, non-aging and chemically neutral. The product is easy and quick to use.